Please contact ACTI for more information on Hazard Assessment & Control training.

⚠️ Hazard Assessment & Control Overview

🔍 Click to Expand

The **Hazard Assessment & Control Program** is designed to help workers and employers **identify, assess, and control workplace hazards**. This training aligns with **Alberta OH&S regulations** and supports a proactive approach to workplace safety.

📌 Key Learning Objectives:

- ✅ Understand the **importance of hazard assessments** in maintaining a safe workplace.

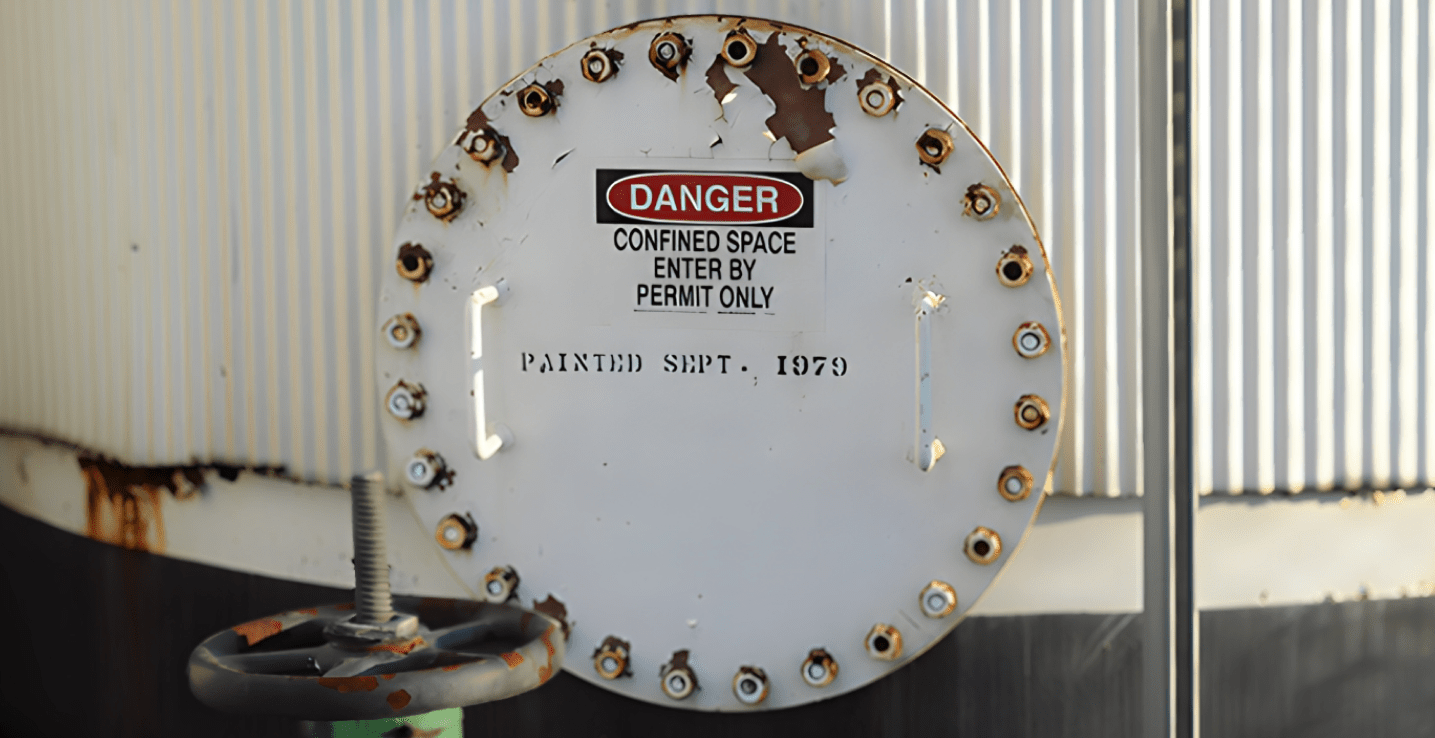

- ✅ Identify **common workplace hazards** and associated risks.

- ✅ Develop **hazard control measures** using the **Hierarchy of Controls**.

- ✅ Implement **effective hazard assessment techniques** in real work environments.

- ✅ Promote a **strong safety culture** through teamwork and compliance with safety regulations.

⚠️ What Causes Most Workplace Injuries?

According to safety statistics, **human error** accounts for **80-90% of workplace injuries**. Factors such as **stress, fatigue, dehydration, and burnout** increase the likelihood of accidents.

👷 Who Is Most at Risk?

**New and young workers** are at a greater risk of injury due to their lack of experience and familiarity with workplace hazards. They may be hesitant to report unsafe conditions or ask for help.

📋 Alberta OH&S Requirements for Hazard Assessment

Under **Part 2 of Alberta's OH&S Code**, employers must:

- 🔹 Conduct **hazard assessments before work begins**.

- 🔹 Document hazard assessments and update them regularly.

- 🔹 Involve workers in hazard identification and control measures.

- 🔹 Implement **risk elimination and control measures** to ensure worker safety.

🛠️ Steps to Conduct a Hazard Assessment

- Step 1: Identify Hazards – Examine workplace processes, equipment, and materials to find potential risks.

- Step 2: Assess the Risk – Determine **likelihood and severity** of each hazard.

- Step 3: Implement Control Measures – Use the **Hierarchy of Controls** to mitigate risks.

- Step 4: Evaluate Effectiveness – Monitor and adjust controls as necessary.

🔹 The Hierarchy of Controls

- ✅ **Elimination** – Remove the hazard entirely.

- ✅ **Substitution** – Replace hazardous materials or equipment with safer alternatives.

- ✅ **Engineering Controls** – Modify work environments (e.g., ventilation, barriers).

- ✅ **Administrative Controls** – Implement policies, procedures, and training.

- ✅ **Personal Protective Equipment (PPE)** – Use protective gear as the last line of defense.

⚠️ Field Level Hazard Assessments (FLHA)

FLHA should be conducted when:

- ✅ Starting a **new job or shift**.

- ✅ **New workers** join the site.

- ✅ **Worksite conditions** change (weather, tools, procedures).

- ✅ **Unexpected hazards** arise during work.

🛑 Common Workplace Hazards:

- 🔥 **Physical Hazards** – Falls, moving machinery, electrical exposure.

- ☣️ **Chemical Hazards** – Toxic gases, corrosive substances, flammable materials.

- 🦠 **Biological Hazards** – Viruses, bacteria, mold, insect bites.

- 🚜 **Mechanical Hazards** – Moving vehicles, heavy machinery, faulty equipment.

- 🧠 **Human Factors** – Fatigue, stress, distractions, risk tolerance.

✅ Hazard Control Best Practices

- ✅ Conduct **daily hazard assessments** before starting work.

- ✅ Report and document hazards **immediately**.

- ✅ Ensure **proper training** for all employees.

- ✅ Use **correct PPE and follow safe work procedures**.

- ✅ Maintain **housekeeping and equipment maintenance** to prevent hazards.

📜 Course Completion & Certification:

To successfully complete this course, participants must:

- ✅ Complete **Spot the Hazards Practicals** with 100% passing grade (unlimited attempts allowed).

- ✅ Pass the **Final Exam** with a **100% score**.

- ✅ Submit the **mandatory feedback form** after the exam.

Upon completion, participants will receive an **ACTI Hazard Assessment & Control Certificate**.

📞 Contact ACTI:

For more information on **Hazard Assessment & Control Training**, please contact ACTI.

🔍 Click to Expand: ACTI Air Purifying Respirator (APR) Training Overview

📌 ACTI Air Purifying Respirator (APR) Training Overview

The ACTI Air Purifying Respirator (APR) Training Program is designed to equip workers with the knowledge and skills required to safely use, inspect, and maintain air-purifying respirators. This training aligns with Occupational Health & Safety (OH&S) regulations, CSA Z94.4 standards, and industry best practices, ensuring compliance and workplace safety.

Participants will learn to identify airborne contaminants, select appropriate APRs, perform fit testing, conduct pre-use inspections, and maintain respiratory equipment. The course covers filtration principles, cartridge selection, hazard assessment, and emergency procedures.

🔹 Key Learning Modules:

- Legislation & Standards: Understanding OH&S regulations, CSA Z94.4, and employer responsibilities for respiratory protection.

- Why Respiratory Protection? Identifying the need for APRs, health risks, and regulatory requirements.

- Types of Air-Purifying Respirators: Full-face, half-face, disposable masks, and powered air-purifying respirators (PAPR).

- Filtration & Cartridge Selection: Understanding filter types, gas/vapor cartridges, color coding, and assigned protection factors (APF).

- Fit Testing & Facial Requirements: Performing qualitative and quantitative fit testing, facial hair policies, and ensuring a proper seal.

- Pre-Use Inspection & Fit Checks: Identifying defects, conducting negative/positive pressure fit tests, and ensuring respirator functionality.

- Storage, Maintenance & Cleaning: Proper cleaning, disinfection, storage, and replacement schedules for filters and cartridges.

- Emergency Procedures & Limitations: Recognizing IDLH (Immediately Dangerous to Life or Health) atmospheres and APR limitations.

✅ Upon Completion:

Participants will be able to:

- ✅ Understand and apply OH&S and CSA Z94.4 regulations regarding air-purifying respirators.

- ✅ Identify airborne contaminants and select the appropriate respirator and filter/cartridge.

- ✅ Perform pre-use inspections to ensure APRs are in proper working condition.

- ✅ Conduct qualitative and quantitative fit testing to verify a secure and effective seal.

- ✅ Properly don, doff, and adjust APRs for effective protection in hazardous environments.

- ✅ Maintain, clean, and store APRs to ensure compliance with industry best practices.

- ✅ Recognize APR limitations and identify situations where supplied-air respirators are required.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an ACTI Air Purifying Respirator (APR) Certification, recognized across Canada, ensuring they are qualified to use and maintain air-purifying respirators in industrial, construction, and hazardous work environments.

🔍 Click to Expand: ACTI WHMIS 2015 Training Overview

The ACTI WHMIS 2015 Training Program provides workers with the essential knowledge and skills to understand and apply the Workplace Hazardous Materials Information System (WHMIS) 2015. This training ensures compliance with Occupational Health & Safety (OH&S) regulations, the Hazardous Products Act, and industry best practices, promoting workplace safety and regulatory adherence.

Participants will learn to identify hazardous materials, interpret Safety Data Sheets (SDS), understand hazard classification, and apply safe handling procedures. The course covers WHMIS legislation, hazard communication, labeling systems, emergency response, and worker responsibilities.

📌 Key Learning Modules:

- Legislation & Regulations: Understanding WHMIS 2015, OH&S laws, and employer/worker responsibilities.

- Hazardous Products & Classification: Identifying hazardous materials and recognizing hazard classes and categories.

- WHMIS Pictograms & Labeling: Recognizing WHMIS symbols, supplier labels, and workplace labels.

- Safety Data Sheets (SDS): How to read and interpret SDS for proper handling, storage, and disposal of chemicals.

- Hazard Controls & Safe Work Practices: Implementing control measures, using PPE, and reducing exposure risks.

- Emergency Procedures & First Aid: Responding to spills, fires, leaks, and worker exposure incidents.

- WHMIS vs. GHS (Globally Harmonized System): Understanding the global standard and its alignment with WHMIS.

✅ Upon Completion:

Participants who successfully complete the **ACTI WHMIS 2015 Training Program** will be able to:

- ✅ Understand and apply WHMIS 2015 regulations and OH&S requirements.

- ✅ Identify hazardous materials and recognize WHMIS hazard classes and pictograms.

- ✅ Read and interpret supplier labels and workplace labels.

- ✅ Locate and use Safety Data Sheets (SDS) to assess chemical hazards.

- ✅ Implement safe handling, storage, and disposal practices for hazardous products.

- ✅ Respond appropriately to hazardous material spills, leaks, and exposure incidents.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete any required practical evaluations.

Upon meeting all course requirements, participants will receive an ACTI WHMIS 2015 Certification, recognized across Canada, demonstrating their proficiency in safely managing hazardous materials in industrial, construction, and workplace environments.

🔍 Cliquez pour Développer : Programme de Formation ACTI pour Chariots Élévateurs

Le Programme de Formation ACTI pour chariots élévateurs est conçu pour fournir aux participants les connaissances et compétences nécessaires à l’exploitation sécuritaire des chariots élévateurs à contrepoids et télescopiques dans divers environnements de travail. La formation est conforme aux réglementations de la SST de l’Alberta, aux normes CSA B335 et aux meilleures pratiques de l’industrie, assurant ainsi la sécurité et la conformité en milieu de travail.

Les participants apprendront à effectuer des inspections de l’équipement, à manœuvrer en toute sécurité, à manipuler correctement les charges et à identifier les risques liés à l’utilisation des chariots élévateurs. Le cours couvre les catégories de chariots élévateurs, les principes de stabilité, les procédures d’exploitation sécuritaire, la reconnaissance des dangers et la réponse aux urgences.

📌 Modules Clés d’Apprentissage :

- Normes réglementaires et conformité : Comprendre les exigences de la SST, les normes CSA B335 et les responsabilités des employeurs et des travailleurs.

- Anatomie et composants des chariots élévateurs : Identifier les composants essentiels, effectuer des inspections préalables et comprendre la capacité de charge.

- Stabilité, manipulation des charges et estimation du poids : Apprendre les notions de centre de gravité, les principes d’équilibre et les techniques de manipulation des charges.

- Techniques de conduite sécuritaire : Manœuvrer dans diverses conditions, opérer en zones à forte circulation et prévenir les risques de basculement.

- Dangers courants et prévention des risques : Identifier les dangers potentiels, tels que les collisions avec des piétons, l’instabilité des charges et le contact avec les lignes électriques.

- Préparation aux urgences et intervention en cas d’incident : Mettre en œuvre des procédures d’arrêt sécuritaire, respecter les protocoles de stationnement et planifier les interventions d’urgence.

✅ À l’issue de la formation :

- ✅ Comprendre et appliquer les réglementations de la SST, les normes CSA B335 et les exigences spécifiques aux chariots élévateurs sur site.

- ✅ Effectuer des inspections préalables à l’utilisation et identifier les défaillances nécessitant un entretien ou une réparation.

- ✅ Manœuvrer en toute sécurité les chariots élévateurs à contrepoids et télescopiques, en maintenant la stabilité et en manipulant les charges correctement.

- ✅ Reconnaître les dangers courants liés aux chariots élévateurs et appliquer les meilleures pratiques pour prévenir les incidents en milieu de travail.

- ✅ Élaborer et suivre des plans d’intervention d’urgence en cas d’incidents ou de pannes d’équipement.

- ✅ Réussir une évaluation des connaissances théoriques (minimum 80 %) ainsi qu’une évaluation pratique.

Les participants qui remplissent toutes les exigences du cours recevront une certification d’opérateur de chariots élévateurs ACTI, reconnue à travers le Canada, attestant de leur qualification pour l’exploitation sécuritaire des chariots élévateurs dans les secteurs de la construction, de l’industrie et de l’entreposage.

🔍 Click to Expand: ACTI Respiratory Protective Equipment (RPE) Training Overview

📌 ACTI Respiratory Protective Equipment (RPE) Training Overview

The ACTI Respiratory Protective Equipment (RPE) Training Program is designed to provide workers with the knowledge and skills necessary to correctly use, inspect, and maintain respiratory protective equipment in compliance with OH&S regulations, CSA Z94.4 standards, and industry best practices. This course ensures participants understand the importance of respiratory protection in hazardous work environments.

Participants will learn to identify respiratory hazards, select appropriate RPE, perform fit testing, conduct pre-use inspections, and follow emergency procedures. The course covers legislation, types of respirators, maintenance, cleaning, and practical application.

🔹 Key Learning Modules:

- Legislation & Standards: Understanding OH&S regulations, CSA Z94.4, and employer responsibilities for respiratory protection.

- Types of Respiratory Protective Equipment: Identifying and selecting appropriate respirators, including SCBA and SABA.

- Facial Requirements & Fit Testing: Proper fit testing techniques, facial hair policies, and ensuring a secure seal.

- Inspection, Maintenance & Cleaning: Conducting pre-use checks, cleaning, storing, and maintaining respiratory equipment.

- SCBA (Self-Contained Breathing Apparatus): Inspection, donning, doffing, and troubleshooting SCBA systems.

- SABA (Supplied Air Breathing Apparatus): Understanding components, inspection, and safe operation.

- Environmental Considerations: Operating in extreme temperatures, confined spaces, and oxygen-deficient atmospheres.

- Emergency Response & Air Quality: Identifying IDLH (Immediately Dangerous to Life or Health) conditions and emergency procedures.

✅ Upon Completion:

Participants will be able to:

- ✅ Understand and apply OH&S and CSA Z94.4 regulations regarding respiratory protection.

- ✅ Identify respiratory hazards and determine the appropriate protective equipment.

- ✅ Perform pre-use inspections and ensure RPE is functioning correctly.

- ✅ Conduct proper fit testing using qualitative and quantitative methods.

- ✅ Use SCBA and SABA safely, including donning, doffing, and air supply management.

- ✅ Maintain, clean, and store RPE to ensure long-term usability and compliance.

- ✅ Recognize and respond to emergency situations requiring respiratory protection.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an ACTI Respiratory Protective Equipment (RPE) Certification, recognized across Canada, ensuring they are qualified to use and maintain respiratory protective equipment in industrial, construction, and hazardous work environments.