The ACTI Off-Campus Worksite Inspection Training Program equips educators, workplace supervisors, and safety personnel with the knowledge and skills necessary to conduct thorough safety inspections of off-campus work placements. This course aligns with Occupational Health & Safety (OH&S) regulations and best practices for ensuring a safe and compliant learning environment for students participating in work-integrated learning programs.

📌 Key Learning Modules:

- Regulatory Requirements & Due Diligence: Understanding OH&S legislation, employer/student responsibilities, and risk management.

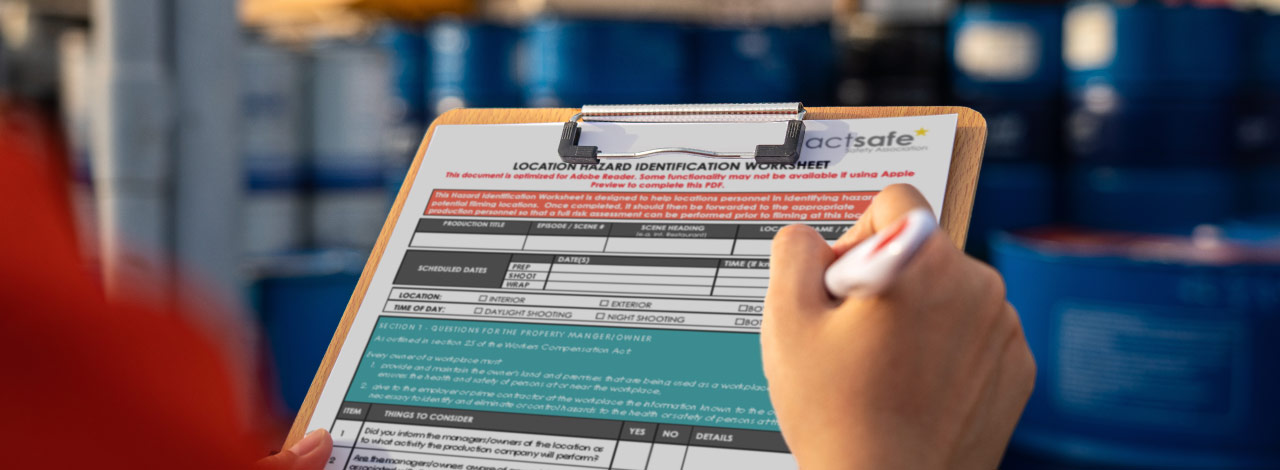

- Hazard Identification & Risk Assessment: Recognizing physical, chemical, biological, and ergonomic hazards in the workplace.

- Worksite Inspection Techniques: Learning how to conduct structured safety inspections, evaluate employer compliance, and document findings.

- Student Health & Safety Considerations: Implementing hazard awareness, training, and PPE requirements to safeguard student workers.

- Incident Reporting & Emergency Preparedness: Developing response plans for workplace accidents and ensuring WCB compliance.

- Safe Work Practices & Cultural Awareness: Understanding workplace expectations, mentorship strategies, and behavioral safety for new workers.

✅ Upon Completion:

Participants will be able to:

- ✅ Understand and apply Alberta OH&S legislation and student safety regulations.

- ✅ Conduct effective worksite inspections, identifying and documenting potential hazards.

- ✅ Assess employer compliance and ensure due diligence in workplace safety.

- ✅ Recognize and mitigate risks that affect student workers, young workers, and new employees.

- ✅ Implement safe work practices and hazard control measures to maintain a secure learning environment.

- ✅ Develop emergency response procedures and incident reporting protocols to comply with Workers’ Compensation Board (WCB) requirements.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete the practical evaluation.

Upon meeting all course requirements, participants will receive an ACTI Off-Campus Worksite Inspection Certification, recognized across Canada, ensuring they are qualified to inspect and evaluate work placements for student safety and compliance.

The ACTI Fire Watch Training Program provides essential knowledge and practical skills for personnel responsible for monitoring fire hazards in hot work environments. This training aligns with Occupational Health & Safety (OH&S) regulations, the provincial Fire Codes, and NFPA 51B standards, ensuring compliance and workplace safety.

🔥 Key Learning Modules:

- Fire Watch Roles & Responsibilities: Understanding duties, authority, and the importance of due diligence.

- Fire Safety Regulations & Compliance: Reviewing OH&S, NFPA standards, and employer responsibilities.

- Fire Hazards & Prevention: Identifying potential fire risks, ignition sources, and fire protection measures.

- Hot Work Operations & Permits: Learning permitting procedures, worksite preparations, and fire prevention strategies.

- Fire Extinguishers & Suppression Techniques: Understanding fire classifications, extinguisher types, and proper usage (PASS method).

- Emergency Response & Incident Management: Developing rescue plans, communication procedures, and post-fire watch protocols.

- Case Studies & Practical Scenarios: Analyzing real-world incidents to reinforce learning and improve fire prevention awareness.

✅ Upon Completion:

Participants will be able to:

- ✅ Understand and apply OH&S legislation and NFPA standards related to fire safety.

- ✅ Identify fire hazards and assess risks associated with hot work operations.

- ✅ Properly conduct fire watch duties, ensuring a safe worksite before, during, and after hot work.

- ✅ Use fire extinguishers correctly, applying the PASS method to suppress fires safely.

- ✅ Implement emergency response procedures, including evacuation, fire suppression, and incident reporting.

- ✅ Monitor work areas post-hot work, maintaining a fire watch for at least one hour after work completion as per the National Fire Code.

- ✅ Pass a written knowledge assessment (minimum 75%) and successfully complete the practical skills evaluation.

Participants who meet all course requirements will receive an ACTI Fire Watch Certification, recognized across Canada, ensuring they are qualified to monitor and respond to fire hazards in industrial and commercial settings.

The **ACTI Fall Protection Training Program** is designed to equip workers with the **knowledge and skills required to work safely at heights**, ensuring compliance with ** OH&S regulations, CSA Z259 standards, and industry best practices**.

Participants will learn how to **identify fall hazards, select appropriate fall protection systems, use equipment correctly, and develop rescue plans**. The course covers **regulatory requirements, fall arrest systems, anchor points, inspection procedures, and emergency response**.

📌 Key Learning Modules:

- Legislation & Worker Responsibilities: Understanding OH&S regulations, CSA Z259 standards, and employer/worker obligations.

- Hazard Recognition & Risk Assessment: Identifying common fall hazards and assessing worksite risks.

- Hierarchy of Controls: Exploring fall prevention, fall arrest, and fall restraint systems.

- Fall Protection Equipment: Proper selection, inspection, and use of harnesses, lanyards, anchor points, and self-retracting lifelines.

- Work Access & Platforms: Safe use of ladders, scaffolds, swing stages, and MEWPs.

- Emergency Response & Rescue Planning: Developing effective fall rescue plans and understanding suspension trauma risks.

✅ Upon Completion:

Upon successfully completing the **ACTI Fall Protection Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA Z259 standards, and worksite-specific fall protection requirements.

- ✅ **Recognize fall hazards** and implement control measures to reduce risks.

- ✅ **Properly inspect and use** fall protection equipment, including harnesses, lanyards, lifelines, and anchor points.

- ✅ **Safely work on elevated platforms, ladders, and scaffolds** while maintaining compliance with fall protection regulations.

- ✅ **Develop and execute emergency response plans** for fall-related incidents, including worker rescue.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI Fall Protection Certification**, recognized across **Canada**, ensuring they are qualified to work safely at heights in **construction, industrial, and maintenance environments**.

🔍 Click to Expand: MEWP Training Overview

The **ACTI Mobile Elevated Work Platform (MEWP) Training Program** is designed to provide participants with the **knowledge and skills required to safely operate MEWPs in various work environments**. This training aligns with ** OH&S regulations, CSA B354 standards, and industry best practices**, ensuring compliance and operational safety.

Participants will learn how to **identify hazards, conduct equipment inspections, operate MEWPs safely, and execute emergency procedures**. The course covers **MEWP classifications, stability principles, fall protection, safe work practices, and emergency response**.

📌 Key Learning Modules:

- Regulatory Standards & Compliance: Understanding OH&S requirements, CSA B354 standards, and employer/worker responsibilities.

- MEWP Types & Components: Identifying different types of MEWPs, their components, and required inspections.

- Pre-Use Inspections & Maintenance: Conducting daily inspections and understanding maintenance requirements.

- Safe Operation & Stability: Proper machine operation, load capacity, working on slopes, and avoiding tip-overs.

- Fall Protection & Worksite Safety: Implementing fall protection measures, hazard assessments, and exclusion zones.

- Emergency Preparedness & Rescue Plans: Understanding rescue procedures in case of machine failure or operator distress.

✅ Upon Completion:

Upon successfully completing the **ACTI MEWP Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA B354 standards, and site-specific MEWP requirements.

- ✅ **Conduct pre-use inspections** and recognize defects that require maintenance or repair.

- ✅ **Safely operate MEWPs** while maintaining stability, avoiding hazards, and following proper work procedures.

- ✅ **Implement fall protection measures** and recognize the importance of safe work practices at height.

- ✅ **Develop and follow emergency action plans** for rescue operations and incident response.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI MEWP Operator Certification**, recognized across **Canada**, ensuring they are qualified to operate MEWPs safely in **construction, industrial, and maintenance environments**.

🔍 Click to Expand: Confined Space Entry & Attendant Training Overview

The **ACTI Confined Space Entry & Attendant Training Program** is designed to provide workers with the **knowledge and skills necessary to safely enter, monitor, and work in confined spaces**. This training aligns with ** OH&S regulations, CSA Z1006 standards, and industry best practices**, ensuring compliance and workplace safety.

Participants will learn how to **identify confined space hazards, implement control measures, follow safe entry procedures, and perform rescue operations**. The course covers **hazard assessment, atmospheric testing, isolation procedures, personal protective equipment (PPE), and emergency response**.

📌 Key Learning Modules:

- Legislation & Regulatory Requirements: Understanding OH&S, CSA Z1006, and employer/worker obligations.

- Hazard Identification & Control Measures: Recognizing common confined space hazards, including atmospheric, mechanical, and engulfment risks.

- Entry Procedures & Permits: Safe work permits, isolation, atmospheric monitoring, and attendant responsibilities.

- Personal Protective Equipment (PPE): Proper selection, use, and inspection of harnesses, respiratory protection, and gas detection equipment.

- Rescue Planning & Emergency Procedures: Understanding confined space rescue types, non-entry rescues, and emergency response planning.

✅ Upon Completion:

Upon successfully completing the **ACTI Confined Space Entry & Attendant Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA Z1006, and site-specific confined space entry requirements.

- ✅ **Conduct hazard assessments** and implement control measures to reduce risks.

- ✅ **Perform pre-entry atmospheric testing** and maintain safe conditions throughout the work process.

- ✅ **Properly use PPE and gas detection equipment** to ensure personal safety and compliance.

- ✅ **Carry out the duties of an attendant and entry supervisor** to oversee confined space operations.

- ✅ **Develop and execute emergency action plans** for confined space rescue situations.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI Confined Space Entry & Attendant Certification**, recognized across **Canada**, ensuring they are qualified to safely enter, monitor, and work in confined spaces within **industrial, construction, and maintenance environments**.

🔍 Click to Expand: ACTI Air Purifying Respirator (APR) Training Overview

📌 ACTI Air Purifying Respirator (APR) Training Overview

The ACTI Air Purifying Respirator (APR) Training Program is designed to equip workers with the knowledge and skills required to safely use, inspect, and maintain air-purifying respirators. This training aligns with Occupational Health & Safety (OH&S) regulations, CSA Z94.4 standards, and industry best practices, ensuring compliance and workplace safety.

Participants will learn to identify airborne contaminants, select appropriate APRs, perform fit testing, conduct pre-use inspections, and maintain respiratory equipment. The course covers filtration principles, cartridge selection, hazard assessment, and emergency procedures.

🔹 Key Learning Modules:

- Legislation & Standards: Understanding OH&S regulations, CSA Z94.4, and employer responsibilities for respiratory protection.

- Why Respiratory Protection? Identifying the need for APRs, health risks, and regulatory requirements.

- Types of Air-Purifying Respirators: Full-face, half-face, disposable masks, and powered air-purifying respirators (PAPR).

- Filtration & Cartridge Selection: Understanding filter types, gas/vapor cartridges, color coding, and assigned protection factors (APF).

- Fit Testing & Facial Requirements: Performing qualitative and quantitative fit testing, facial hair policies, and ensuring a proper seal.

- Pre-Use Inspection & Fit Checks: Identifying defects, conducting negative/positive pressure fit tests, and ensuring respirator functionality.

- Storage, Maintenance & Cleaning: Proper cleaning, disinfection, storage, and replacement schedules for filters and cartridges.

- Emergency Procedures & Limitations: Recognizing IDLH (Immediately Dangerous to Life or Health) atmospheres and APR limitations.

✅ Upon Completion:

Participants will be able to:

- ✅ Understand and apply OH&S and CSA Z94.4 regulations regarding air-purifying respirators.

- ✅ Identify airborne contaminants and select the appropriate respirator and filter/cartridge.

- ✅ Perform pre-use inspections to ensure APRs are in proper working condition.

- ✅ Conduct qualitative and quantitative fit testing to verify a secure and effective seal.

- ✅ Properly don, doff, and adjust APRs for effective protection in hazardous environments.

- ✅ Maintain, clean, and store APRs to ensure compliance with industry best practices.

- ✅ Recognize APR limitations and identify situations where supplied-air respirators are required.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an ACTI Air Purifying Respirator (APR) Certification, recognized across Canada, ensuring they are qualified to use and maintain air-purifying respirators in industrial, construction, and hazardous work environments.