🔍 Click to Expand: ACTI Wildlife Awareness Training Overview

📌 ACTI Wildlife Awareness Training Overview

The ACTI Wildlife Awareness Training Program is designed to provide workers with the knowledge and skills required to recognize and respond to wildlife encounters in remote or wilderness work environments. This training aligns with Occupational Health & Safety (OH&S) regulations and industry best practices, ensuring compliance and workplace safety.

Participants will learn to identify wildlife hazards, implement avoidance strategies, properly use deterrents, and respond effectively to encounters with various species. The course covers bear awareness, cougars, wolves, moose, foxes, and other wildlife safety considerations.

🔹 Key Learning Modules:

- Legislation & Compliance: Understanding OH&S regulations and employer responsibilities for wildlife safety.

- Recognizing Wildlife Hazards: Identifying animal tracks, scat, signs of recent activity, and high-risk areas.

- Bear Awareness: Behavior, habitat, avoiding encounters, and response to black and grizzly bear encounters.

- Cougars, Wolves, and Lynx: Identifying predatory animal behavior and proper response to encounters.

- Moose, Caribou, and Other Species: Safe work practices around large herbivores in the wild.

- Wildlife Deterrents: Proper use of bear spray, noisemakers, air horns, and other deterrent strategies.

- Emergency Response & Reporting: Steps to take if wildlife is aggressive, injured, or present in the work area.

- Working in Bear Country: Best practices for camps, food storage, garbage management, and reducing attractants.

✅ Upon Completion:

Participants will be able to:

- ✅ Understand and apply OH&S regulations and industry standards for wildlife awareness.

- ✅ Identify animal tracks, scat, and habitat indicators to assess wildlife presence.

- ✅ Implement avoidance strategies to minimize wildlife encounters in remote work locations.

- ✅ Respond appropriately to bear, cougar, wolf, and other wildlife encounters.

- ✅ Demonstrate safe use of wildlife deterrents such as bear spray and noisemakers.

- ✅ Follow best practices for working safely in bear country, including food and waste management.

- ✅ Report wildlife hazards and respond effectively to emergency situations.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an ACTI Wildlife Awareness Certification, recognized across Canada, ensuring they are qualified to work safely in wildlife-prone environments, including forestry, oil and gas, remote construction, and environmental fieldwork.

🔍 Click to Expand: ACTI Respiratory Protective Equipment (RPE) Training Overview

📌 ACTI Respiratory Protective Equipment (RPE) Training Overview

The ACTI Respiratory Protective Equipment (RPE) Training Program is designed to provide workers with the knowledge and skills necessary to correctly use, inspect, and maintain respiratory protective equipment in compliance with OH&S regulations, CSA Z94.4 standards, and industry best practices. This course ensures participants understand the importance of respiratory protection in hazardous work environments.

Participants will learn to identify respiratory hazards, select appropriate RPE, perform fit testing, conduct pre-use inspections, and follow emergency procedures. The course covers legislation, types of respirators, maintenance, cleaning, and practical application.

🔹 Key Learning Modules:

- Legislation & Standards: Understanding OH&S regulations, CSA Z94.4, and employer responsibilities for respiratory protection.

- Types of Respiratory Protective Equipment: Identifying and selecting appropriate respirators, including SCBA and SABA.

- Facial Requirements & Fit Testing: Proper fit testing techniques, facial hair policies, and ensuring a secure seal.

- Inspection, Maintenance & Cleaning: Conducting pre-use checks, cleaning, storing, and maintaining respiratory equipment.

- SCBA (Self-Contained Breathing Apparatus): Inspection, donning, doffing, and troubleshooting SCBA systems.

- SABA (Supplied Air Breathing Apparatus): Understanding components, inspection, and safe operation.

- Environmental Considerations: Operating in extreme temperatures, confined spaces, and oxygen-deficient atmospheres.

- Emergency Response & Air Quality: Identifying IDLH (Immediately Dangerous to Life or Health) conditions and emergency procedures.

✅ Upon Completion:

Participants will be able to:

- ✅ Understand and apply OH&S and CSA Z94.4 regulations regarding respiratory protection.

- ✅ Identify respiratory hazards and determine the appropriate protective equipment.

- ✅ Perform pre-use inspections and ensure RPE is functioning correctly.

- ✅ Conduct proper fit testing using qualitative and quantitative methods.

- ✅ Use SCBA and SABA safely, including donning, doffing, and air supply management.

- ✅ Maintain, clean, and store RPE to ensure long-term usability and compliance.

- ✅ Recognize and respond to emergency situations requiring respiratory protection.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an ACTI Respiratory Protective Equipment (RPE) Certification, recognized across Canada, ensuring they are qualified to use and maintain respiratory protective equipment in industrial, construction, and hazardous work environments.

🔍 Click to Expand: Fall Protection Training Overview

The **ACTI Fall Protection Training Program** is designed to equip workers with the **knowledge and skills required to work safely at heights**, ensuring compliance with ** OH&S regulations, CSA Z259 standards, and industry best practices**.

Participants will learn how to **identify fall hazards, select appropriate fall protection systems, use equipment correctly, and develop rescue plans**. The course covers **regulatory requirements, fall arrest systems, anchor points, inspection procedures, and emergency response**.

📌 Key Learning Modules:

- Legislation & Worker Responsibilities: Understanding OH&S regulations, CSA Z259 standards, and employer/worker obligations.

- Hazard Recognition & Risk Assessment: Identifying common fall hazards and assessing worksite risks.

- Hierarchy of Controls: Exploring fall prevention, fall arrest, and fall restraint systems.

- Fall Protection Equipment: Proper selection, inspection, and use of harnesses, lanyards, anchor points, and self-retracting lifelines.

- Work Access & Platforms: Safe use of ladders, scaffolds, swing stages, and MEWPs.

- Emergency Response & Rescue Planning: Developing effective fall rescue plans and understanding suspension trauma risks.

✅ Upon Completion:

Upon successfully completing the **ACTI Fall Protection Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA Z259 standards, and worksite-specific fall protection requirements.

- ✅ **Recognize fall hazards** and implement control measures to reduce risks.

- ✅ **Properly inspect and use** fall protection equipment, including harnesses, lanyards, lifelines, and anchor points.

- ✅ **Safely work on elevated platforms, ladders, and scaffolds** while maintaining compliance with fall protection regulations.

- ✅ **Develop and execute emergency response plans** for fall-related incidents, including worker rescue.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI Fall Protection Certification**, recognized across **Canada**, ensuring they are qualified to work safely at heights in **construction, industrial, and maintenance environments**.

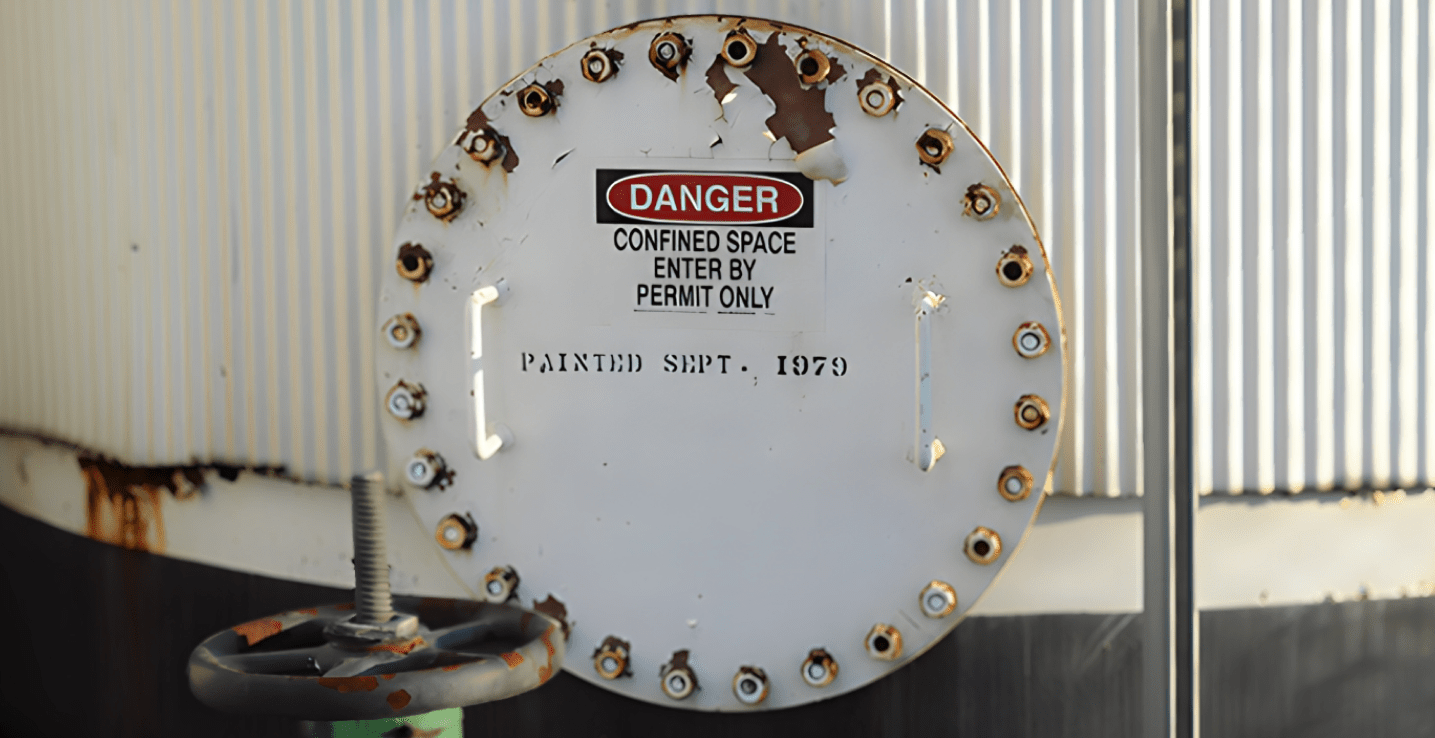

🔍 Click to Expand: Confined Space Entry & Attendant Training Overview

The **ACTI Confined Space Entry & Attendant Training Program** is designed to provide workers with the **knowledge and skills necessary to safely enter, monitor, and work in confined spaces**. This training aligns with ** OH&S regulations, CSA Z1006 standards, and industry best practices**, ensuring compliance and workplace safety.

Participants will learn how to **identify confined space hazards, implement control measures, follow safe entry procedures, and perform rescue operations**. The course covers **hazard assessment, atmospheric testing, isolation procedures, personal protective equipment (PPE), and emergency response**.

📌 Key Learning Modules:

- Legislation & Regulatory Requirements: Understanding OH&S, CSA Z1006, and employer/worker obligations.

- Hazard Identification & Control Measures: Recognizing common confined space hazards, including atmospheric, mechanical, and engulfment risks.

- Entry Procedures & Permits: Safe work permits, isolation, atmospheric monitoring, and attendant responsibilities.

- Personal Protective Equipment (PPE): Proper selection, use, and inspection of harnesses, respiratory protection, and gas detection equipment.

- Rescue Planning & Emergency Procedures: Understanding confined space rescue types, non-entry rescues, and emergency response planning.

✅ Upon Completion:

Upon successfully completing the **ACTI Confined Space Entry & Attendant Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA Z1006, and site-specific confined space entry requirements.

- ✅ **Conduct hazard assessments** and implement control measures to reduce risks.

- ✅ **Perform pre-entry atmospheric testing** and maintain safe conditions throughout the work process.

- ✅ **Properly use PPE and gas detection equipment** to ensure personal safety and compliance.

- ✅ **Carry out the duties of an attendant and entry supervisor** to oversee confined space operations.

- ✅ **Develop and execute emergency action plans** for confined space rescue situations.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI Confined Space Entry & Attendant Certification**, recognized across **Canada**, ensuring they are qualified to safely enter, monitor, and work in confined spaces within **industrial, construction, and maintenance environments**.