🔍 Click to Expand: Lift Truck Training Overview

The **ACTI Lift Truck Training Program** is designed to provide participants with the **knowledge and skills necessary to safely operate counterbalance and telescopic forklifts in various work environments**. This training aligns with **Alberta OH&S regulations, CSA B335 standards, and industry best practices**, ensuring compliance and workplace safety.

Participants will learn how to **conduct equipment inspections, operate lift trucks safely, handle loads correctly, and recognize hazards associated with lift truck operations**. The course covers **forklift classifications, stability principles, safe operating procedures, hazard awareness, and emergency response**.

📌 Key Learning Modules:

- Regulatory Standards & Compliance: Understanding OH&S requirements, CSA B335 standards, and employer/worker responsibilities.

- Lift Truck Anatomy & Components: Identifying key components, performing pre-use inspections, and understanding load capacity.

- Stability, Load Handling & Weight Estimation: Learning about center of gravity, balance principles, and proper load handling.

- Safe Operation & Driving Techniques: Maneuvering in various conditions, operating in high-traffic areas, and avoiding tip-overs.

- Common Hazards & Risk Prevention: Recognizing potential dangers such as pedestrian collisions, load instability, and power line contact.

- Emergency Preparedness & Incident Response: Implementing safe shutdown procedures, parking protocols, and emergency response planning.

✅ Upon Completion:

Upon successfully completing the **ACTI Lift Truck Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA B335 standards, and site-specific lift truck requirements.

- ✅ **Conduct pre-use inspections** and recognize defects that require maintenance or repair.

- ✅ **Safely operate counterbalance and telescopic forklifts** while maintaining stability and handling loads correctly.

- ✅ **Recognize common lift truck hazards** and implement best practices to prevent workplace incidents.

- ✅ **Develop and follow emergency response plans** for lift-related incidents and equipment failures.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI Lift Truck Operator Certification**, recognized across **Canada**, ensuring they are qualified to operate lift trucks safely in **construction, industrial, and warehouse environments**.

🔍 Click to Expand: MEWP Training Overview

The **ACTI Mobile Elevated Work Platform (MEWP) Training Program** is designed to provide participants with the **knowledge and skills required to safely operate MEWPs in various work environments**. This training aligns with ** OH&S regulations, CSA B354 standards, and industry best practices**, ensuring compliance and operational safety.

Participants will learn how to **identify hazards, conduct equipment inspections, operate MEWPs safely, and execute emergency procedures**. The course covers **MEWP classifications, stability principles, fall protection, safe work practices, and emergency response**.

📌 Key Learning Modules:

- Regulatory Standards & Compliance: Understanding OH&S requirements, CSA B354 standards, and employer/worker responsibilities.

- MEWP Types & Components: Identifying different types of MEWPs, their components, and required inspections.

- Pre-Use Inspections & Maintenance: Conducting daily inspections and understanding maintenance requirements.

- Safe Operation & Stability: Proper machine operation, load capacity, working on slopes, and avoiding tip-overs.

- Fall Protection & Worksite Safety: Implementing fall protection measures, hazard assessments, and exclusion zones.

- Emergency Preparedness & Rescue Plans: Understanding rescue procedures in case of machine failure or operator distress.

✅ Upon Completion:

Upon successfully completing the **ACTI MEWP Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA B354 standards, and site-specific MEWP requirements.

- ✅ **Conduct pre-use inspections** and recognize defects that require maintenance or repair.

- ✅ **Safely operate MEWPs** while maintaining stability, avoiding hazards, and following proper work procedures.

- ✅ **Implement fall protection measures** and recognize the importance of safe work practices at height.

- ✅ **Develop and follow emergency action plans** for rescue operations and incident response.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI MEWP Operator Certification**, recognized across **Canada**, ensuring they are qualified to operate MEWPs safely in **construction, industrial, and maintenance environments**.

🔍 Click to Expand: Fall Protection Training Overview

The ACTI Fall Protection Training Program is designed to equip workers with the knowledge and skills required to work safely at heights, ensuring compliance with OH&S regulations, CSA Z259 standards, and industry best practices.

Participants will learn how to identify fall hazards, select appropriate fall protection systems, use equipment correctly, and develop rescue plans. The course covers regulatory requirements, fall arrest systems, anchor points, inspection procedures, and emergency response.

📌 Key Learning Modules:

- Legislation & Worker Responsibilities: Understanding OH&S regulations, CSA Z259 standards, and employer/worker obligations.

- Hazard Recognition & Risk Assessment: Identifying common fall hazards and assessing worksite risks.

- Hierarchy of Controls: Exploring fall prevention, fall arrest, and fall restraint systems.

- Fall Protection Equipment: Proper selection, inspection, and use of harnesses, lanyards, anchor points, and self-retracting lifelines.

- Work Access & Platforms: Safe use of ladders, scaffolds, swing stages, and MEWPs.

- Emergency Response & Rescue Planning: Developing effective fall rescue plans and understanding suspension trauma risks.

✅ Upon Completion:

Upon successfully completing the ACTI Fall Protection Training Program, participants will be able to:

- ✅ Understand and apply OH&S regulations, CSA Z259 standards, and worksite-specific fall protection requirements.

- ✅ Recognize fall hazards and implement control measures to reduce risks.

- ✅ Properly inspect and use fall protection equipment, including harnesses, lanyards, lifelines, and anchor points.

- ✅ Safely work on elevated platforms, ladders, and scaffolds while maintaining compliance with fall protection regulations.

- ✅ Develop and execute emergency response plans for fall-related incidents, including worker rescue.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an ACTI Fall Protection Certification, recognized across Canada, ensuring they are qualified to work safely at heights in construction, industrial, and maintenance environments.

🌎 National Program Mobility:

As part of ACTI’s national safety training initiative, this Fall Protection program is designed to support workers across all provinces and territories in Canada. The base course provides a consistent standard that meets the core requirements of CSA Z259 and national OH&S expectations, offering a strong foundation for safe work at heights anywhere in the country.

To ensure full compliance with jurisdiction-specific legislation, ACTI offers optional add-on modules tailored to the unique fall protection regulations of each province and territory—including Alberta, British Columbia, Ontario, Quebec, and the northern territories. These modules align with local OH&S Acts, Codes, and safety enforcement standards, giving workers and employers confidence in meeting all site and legal obligations.

This modular system allows workers to remain fully certified and mobile across Canada, simply by completing the regional module relevant to their work location. It also helps employers maintain compliance while reducing the need for redundant retraining.

📌 Planning work in another province or territory? Register for the corresponding ACTI Provincial Legislation Module to ensure your certification meets local legal and site-specific requirements.

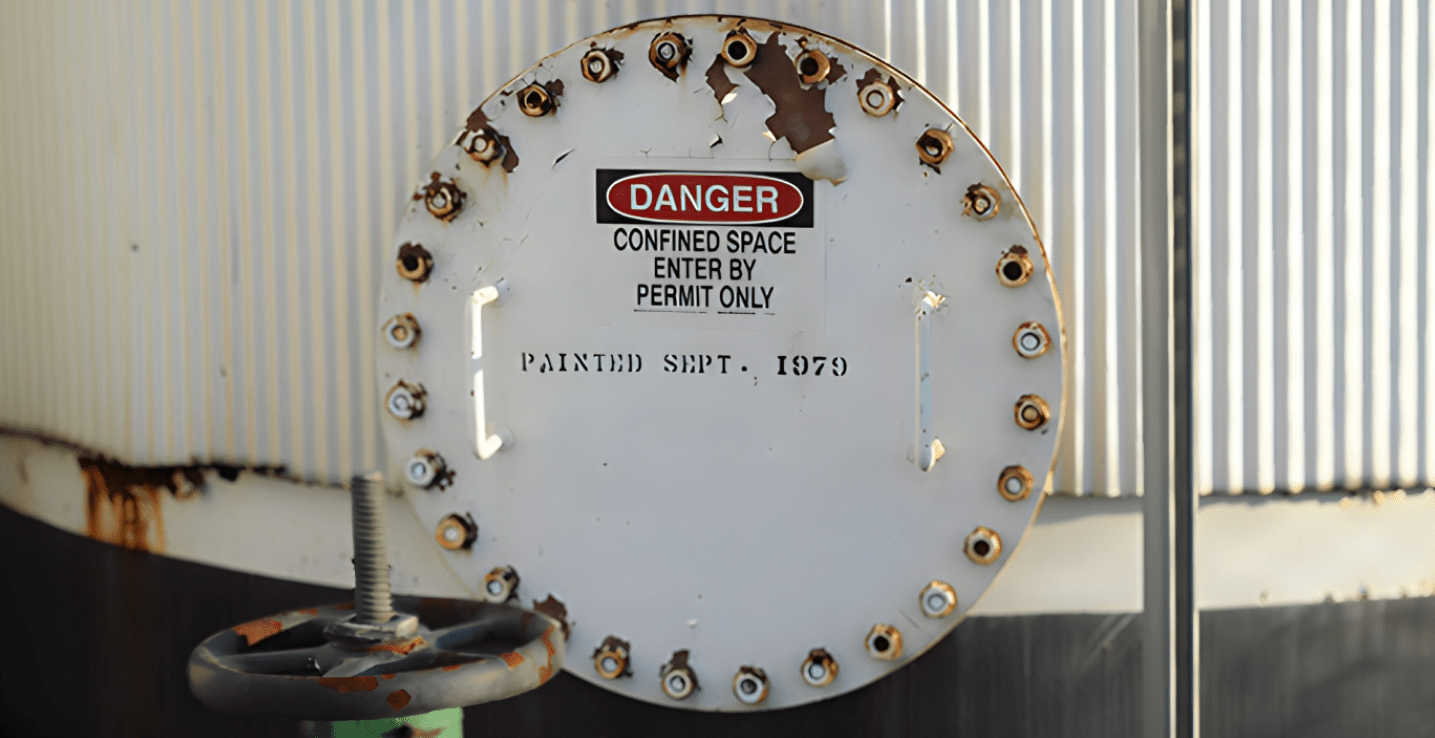

🔍 Click to Expand: Confined Space Entry & Attendant Training Overview

The ACTI Confined Space Entry & Attendant Training Program is designed to provide workers with the knowledge and skills necessary to safely enter, monitor, and work in confined spaces. This training aligns with OH&S regulations, CSA Z1006 standards, and industry best practices, ensuring compliance and workplace safety.

Participants will learn how to identify confined space hazards, implement control measures, follow safe entry procedures, and perform rescue operations. The course covers hazard assessment, atmospheric testing, isolation procedures, personal protective equipment (PPE), and emergency response.

📌 Key Learning Modules:

- Legislation & Regulatory Requirements: Understanding OH&S, CSA Z1006, and employer/worker obligations.

- Hazard Identification & Control Measures: Recognizing common confined space hazards, including atmospheric, mechanical, and engulfment risks.

- Entry Procedures & Permits: Safe work permits, isolation, atmospheric monitoring, and attendant responsibilities.

- Personal Protective Equipment (PPE): Proper selection, use, and inspection of harnesses, respiratory protection, and gas detection equipment.

- Rescue Planning & Emergency Procedures: Understanding confined space rescue types, non-entry rescues, and emergency response planning.

✅ Upon Completion:

Upon successfully completing the ACTI Confined Space Entry & Attendant Training Program, participants will be able to:

- ✅ Understand and apply OH&S regulations, CSA Z1006, and site-specific confined space entry requirements.

- ✅ Conduct hazard assessments and implement control measures to reduce risks.

- ✅ Perform pre-entry atmospheric testing and maintain safe conditions throughout the work process.

- ✅ Properly use PPE and gas detection equipment to ensure personal safety and compliance.

- ✅ Carry out the duties of an attendant and entry supervisor to oversee confined space operations.

- ✅ Develop and execute emergency action plans for confined space rescue situations.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an ACTI Confined Space Entry & Attendant Certification, recognized across Canada, ensuring they are qualified to safely enter, monitor, and work in confined spaces within industrial, construction, and maintenance environments.

🌎 National Program Mobility:

The ACTI training framework is part of a nationally recognized program that supports workers across all provinces and territories in Canada. The base course provides consistent foundational training that adheres to CSA Z1006 and core OH&S principles, ensuring a unified level of competency nationwide.

To meet regional regulatory requirements, ACTI offers optional provincial/territorial legislation modules that align with local OH&S Acts, Codes, and confined space standards. Whether you are working in Alberta, British Columbia, Saskatchewan, Ontario, Quebec, or any other jurisdiction—including the Northwest Territories, Nunavut, and Yukon—these add-ons ensure your training is fully aligned with local laws and employer expectations.

This modular approach empowers workers to remain compliant and employable across Canada, while helping employers meet jurisdiction-specific legislative responsibilities without duplicating entire courses. Workers who move between provinces can simply complete the relevant legislation module to supplement their ACTI base certification.

📌 Planning cross-provincial work? Be sure to register for the appropriate jurisdictional add-on course to ensure full compliance and recognition in your destination province or territory.

🔍 Click to Expand: Fire Watch Training Overview

The ACTI Fire Watch Training Program provides essential knowledge and practical skills for personnel responsible for monitoring fire hazards in hot work environments. This training aligns with Occupational Health & Safety (OH&S) regulations, the provincial Fire Codes, and NFPA 51B standards, ensuring compliance and workplace safety.

🔥 Key Learning Modules:

- Fire Watch Roles & Responsibilities: Understanding duties, authority, and the importance of due diligence.

- Fire Safety Regulations & Compliance: Reviewing OH&S, NFPA standards, and employer responsibilities.

- Fire Hazards & Prevention: Identifying potential fire risks, ignition sources, and fire protection measures.

- Hot Work Operations & Permits: Learning permitting procedures, worksite preparations, and fire prevention strategies.

- Fire Extinguishers & Suppression Techniques: Understanding fire classifications, extinguisher types, and proper usage (PASS method).

- Emergency Response & Incident Management: Developing rescue plans, communication procedures, and post-fire watch protocols.

- Case Studies & Practical Scenarios: Analyzing real-world incidents to reinforce learning and improve fire prevention awareness.

✅ Upon Completion:

Participants will be able to:

- ✅ Understand and apply OH&S legislation and NFPA standards related to fire safety.

- ✅ Identify fire hazards and assess risks associated with hot work operations.

- ✅ Properly conduct fire watch duties, ensuring a safe worksite before, during, and after hot work.

- ✅ Use fire extinguishers correctly, applying the PASS method to suppress fires safely.

- ✅ Implement emergency response procedures, including evacuation, fire suppression, and incident reporting.

- ✅ Monitor work areas post-hot work, maintaining a fire watch for at least one hour after work completion as per the National Fire Code.

- ✅ Pass a written knowledge assessment (minimum 75%) and successfully complete the practical skills evaluation.

Participants who meet all course requirements will receive an ACTI Fire Watch Certification, recognized across Canada, ensuring they are qualified to monitor and respond to fire hazards in industrial and commercial settings.

🔍 Click to Expand: ACTI WHMIS 2015 Training Overview

The ACTI WHMIS 2015 Training Program provides workers with the essential knowledge and skills to understand and apply the Workplace Hazardous Materials Information System (WHMIS) 2015. This training ensures compliance with Occupational Health & Safety (OH&S) regulations, the Hazardous Products Act, and industry best practices, promoting workplace safety and regulatory adherence.

Participants will learn to identify hazardous materials, interpret Safety Data Sheets (SDS), understand hazard classification, and apply safe handling procedures. The course covers WHMIS legislation, hazard communication, labeling systems, emergency response, and worker responsibilities.

📌 Key Learning Modules:

- Legislation & Regulations: Understanding WHMIS 2015, OH&S laws, and employer/worker responsibilities.

- Hazardous Products & Classification: Identifying hazardous materials and recognizing hazard classes and categories.

- WHMIS Pictograms & Labeling: Recognizing WHMIS symbols, supplier labels, and workplace labels.

- Safety Data Sheets (SDS): How to read and interpret SDS for proper handling, storage, and disposal of chemicals.

- Hazard Controls & Safe Work Practices: Implementing control measures, using PPE, and reducing exposure risks.

- Emergency Procedures & First Aid: Responding to spills, fires, leaks, and worker exposure incidents.

- WHMIS vs. GHS (Globally Harmonized System): Understanding the global standard and its alignment with WHMIS.

✅ Upon Completion:

Participants who successfully complete the **ACTI WHMIS 2015 Training Program** will be able to:

- ✅ Understand and apply WHMIS 2015 regulations and OH&S requirements.

- ✅ Identify hazardous materials and recognize WHMIS hazard classes and pictograms.

- ✅ Read and interpret supplier labels and workplace labels.

- ✅ Locate and use Safety Data Sheets (SDS) to assess chemical hazards.

- ✅ Implement safe handling, storage, and disposal practices for hazardous products.

- ✅ Respond appropriately to hazardous material spills, leaks, and exposure incidents.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete any required practical evaluations.

Upon meeting all course requirements, participants will receive an ACTI WHMIS 2015 Certification, recognized across Canada, demonstrating their proficiency in safely managing hazardous materials in industrial, construction, and workplace environments.

🔍 Click to Expand: ACTI Wildlife Awareness Training Overview

📌 ACTI Wildlife Awareness Training Overview

The ACTI Wildlife Awareness Training Program is designed to provide workers with the knowledge and skills required to recognize and respond to wildlife encounters in remote or wilderness work environments. This training aligns with Occupational Health & Safety (OH&S) regulations and industry best practices, ensuring compliance and workplace safety.

Participants will learn to identify wildlife hazards, implement avoidance strategies, properly use deterrents, and respond effectively to encounters with various species. The course covers bear awareness, cougars, wolves, moose, foxes, and other wildlife safety considerations.

🔹 Key Learning Modules:

- Legislation & Compliance: Understanding OH&S regulations and employer responsibilities for wildlife safety.

- Recognizing Wildlife Hazards: Identifying animal tracks, scat, signs of recent activity, and high-risk areas.

- Bear Awareness: Behavior, habitat, avoiding encounters, and response to black and grizzly bear encounters.

- Cougars, Wolves, and Lynx: Identifying predatory animal behavior and proper response to encounters.

- Moose, Caribou, and Other Species: Safe work practices around large herbivores in the wild.

- Wildlife Deterrents: Proper use of bear spray, noisemakers, air horns, and other deterrent strategies.

- Emergency Response & Reporting: Steps to take if wildlife is aggressive, injured, or present in the work area.

- Working in Bear Country: Best practices for camps, food storage, garbage management, and reducing attractants.

✅ Upon Completion:

Participants will be able to:

- ✅ Understand and apply OH&S regulations and industry standards for wildlife awareness.

- ✅ Identify animal tracks, scat, and habitat indicators to assess wildlife presence.

- ✅ Implement avoidance strategies to minimize wildlife encounters in remote work locations.

- ✅ Respond appropriately to bear, cougar, wolf, and other wildlife encounters.

- ✅ Demonstrate safe use of wildlife deterrents such as bear spray and noisemakers.

- ✅ Follow best practices for working safely in bear country, including food and waste management.

- ✅ Report wildlife hazards and respond effectively to emergency situations.

- ✅ Pass a written knowledge assessment (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an ACTI Wildlife Awareness Certification, recognized across Canada, ensuring they are qualified to work safely in wildlife-prone environments, including forestry, oil and gas, remote construction, and environmental fieldwork.

Please contact ACTI for more information on Hazard Assessment & Control training.

⚠️ Hazard Assessment & Control Overview

🔍 Click to Expand

The **Hazard Assessment & Control Program** is designed to help workers and employers **identify, assess, and control workplace hazards**. This training aligns with **Alberta OH&S regulations** and supports a proactive approach to workplace safety.

📌 Key Learning Objectives:

- ✅ Understand the **importance of hazard assessments** in maintaining a safe workplace.

- ✅ Identify **common workplace hazards** and associated risks.

- ✅ Develop **hazard control measures** using the **Hierarchy of Controls**.

- ✅ Implement **effective hazard assessment techniques** in real work environments.

- ✅ Promote a **strong safety culture** through teamwork and compliance with safety regulations.

⚠️ What Causes Most Workplace Injuries?

According to safety statistics, **human error** accounts for **80-90% of workplace injuries**. Factors such as **stress, fatigue, dehydration, and burnout** increase the likelihood of accidents.

👷 Who Is Most at Risk?

**New and young workers** are at a greater risk of injury due to their lack of experience and familiarity with workplace hazards. They may be hesitant to report unsafe conditions or ask for help.

📋 Alberta OH&S Requirements for Hazard Assessment

Under **Part 2 of Alberta's OH&S Code**, employers must:

- 🔹 Conduct **hazard assessments before work begins**.

- 🔹 Document hazard assessments and update them regularly.

- 🔹 Involve workers in hazard identification and control measures.

- 🔹 Implement **risk elimination and control measures** to ensure worker safety.

🛠️ Steps to Conduct a Hazard Assessment

- Step 1: Identify Hazards – Examine workplace processes, equipment, and materials to find potential risks.

- Step 2: Assess the Risk – Determine **likelihood and severity** of each hazard.

- Step 3: Implement Control Measures – Use the **Hierarchy of Controls** to mitigate risks.

- Step 4: Evaluate Effectiveness – Monitor and adjust controls as necessary.

🔹 The Hierarchy of Controls

- ✅ **Elimination** – Remove the hazard entirely.

- ✅ **Substitution** – Replace hazardous materials or equipment with safer alternatives.

- ✅ **Engineering Controls** – Modify work environments (e.g., ventilation, barriers).

- ✅ **Administrative Controls** – Implement policies, procedures, and training.

- ✅ **Personal Protective Equipment (PPE)** – Use protective gear as the last line of defense.

⚠️ Field Level Hazard Assessments (FLHA)

FLHA should be conducted when:

- ✅ Starting a **new job or shift**.

- ✅ **New workers** join the site.

- ✅ **Worksite conditions** change (weather, tools, procedures).

- ✅ **Unexpected hazards** arise during work.

🛑 Common Workplace Hazards:

- 🔥 **Physical Hazards** – Falls, moving machinery, electrical exposure.

- ☣️ **Chemical Hazards** – Toxic gases, corrosive substances, flammable materials.

- 🦠 **Biological Hazards** – Viruses, bacteria, mold, insect bites.

- 🚜 **Mechanical Hazards** – Moving vehicles, heavy machinery, faulty equipment.

- 🧠 **Human Factors** – Fatigue, stress, distractions, risk tolerance.

✅ Hazard Control Best Practices

- ✅ Conduct **daily hazard assessments** before starting work.

- ✅ Report and document hazards **immediately**.

- ✅ Ensure **proper training** for all employees.

- ✅ Use **correct PPE and follow safe work procedures**.

- ✅ Maintain **housekeeping and equipment maintenance** to prevent hazards.

📜 Course Completion & Certification:

To successfully complete this course, participants must:

- ✅ Complete **Spot the Hazards Practicals** with 100% passing grade (unlimited attempts allowed).

- ✅ Pass the **Final Exam** with a **100% score**.

- ✅ Submit the **mandatory feedback form** after the exam.

Upon completion, participants will receive an **ACTI Hazard Assessment & Control Certificate**.

📞 Contact ACTI:

For more information on **Hazard Assessment & Control Training**, please contact ACTI.