"Call our office to book this training "

🔍 Click to Expand: ACTI Basic Rigging Training Overview

📌 ACTI Basic Rigging Training Overview

The ACTI Basic Rigging Training Program is designed to provide workers with the fundamental knowledge and skills necessary to perform safe rigging and lifting operations. This training follows the Lifting Equipment Engineers Association (LEEA) standards, ensuring compliance with Occupational Health & Safety (OH&S) regulations, CSA standards, and industry best practices.

Participants will learn to identify rigging equipment, calculate load weights, select proper slings, understand lifting angles, inspect rigging gear, and follow best practices for safe lifting operations. The course covers lifting theory, center of gravity, hardware usage, below-the-hook devices, and crane communication.

📌 Course Structure

- Duration: 8 hours (varies based on participant experience).

- Delivery Method: Theory-based presentations, discussions, written exams, and hands-on practical evaluations.

- Assessment: Written exam (minimum 80% pass mark) and practical demonstration of rigging skills.

📌 Key Learning Modules

🔹 1. Legislation & Safety Standards

- LEEA regulations, OH&S standards, CSA compliance, and employer/worker responsibilities.

- Understanding legal obligations and best practices for rigging operations.

🔹 2. Load Weight Calculation & Center of Gravity

- Techniques for estimating and verifying load weights.

- Understanding the center of gravity and its impact on lifting stability.

- Methods for safely balancing and positioning loads.

🔹 3. Sling Angles, Hitches & Stress Factors

- Understanding sling configurations: vertical, choker, and basket hitches.

- Load angle stress and how sling angles affect lifting capacity.

- Best practices for using multiple sling configurations.

🔹 4. Types of Rigging Equipment

- Identification and safe use of synthetic slings, wire rope slings, and chain slings.

- Inspection procedures, load capacity, and maintenance of rigging hardware.

- Proper storage, usage, and rejection criteria.

🔹 5. Hardware & Below-the-Hook Lifting Devices

- Inspection and safe use of shackles, hooks, eyebolts, turnbuckles, master links, and spreader bars.

- Understanding below-the-hook devices such as lifting beams, clamps, magnets, and drum lifters.

- Rigging gear inspections and criteria for removing defective equipment from service.

🔹 6. Crane Considerations & Communication

- Overview of crane types and safe lifting procedures.

- Hand signals and voice communication for directing crane movements.

- Load stability, swing control, and exclusion zone management.

🔹 7. Common Hazards & Risk Mitigation

- Identifying rigging hazards such as unstable loads, overhead power lines, and pinch points.

- Preventing load shifting, equipment failures, and worker injuries.

- Emergency response planning and best practices.

📌 Why Choose ACTI LEEA Basic Rigging Training?

- ✅ Regulatory Compliance: Meets LEEA, CSA, and OH&S rigging safety requirements.

- ✅ Hands-On Learning: Practical exercises to reinforce rigging skills.

- ✅ Industry-Specific Training: Designed for construction, industrial, and heavy-lifting environments.

- ✅ Certification & Tracking: Automated learner progress tracking with instant certification upon completion.

📌 Getting Started

- Enroll in Your Course – Choose the ACTI LEEA Basic Rigging Training program and begin your training.

- Complete Training – Engage with interactive learning, written assessments, and instructor-led sessions.

- Earn Certification – Upon successful completion, receive your ACTI LEEA Basic Rigging Certification.

Ready to get started? Enroll today and enhance your rigging safety and compliance knowledge!

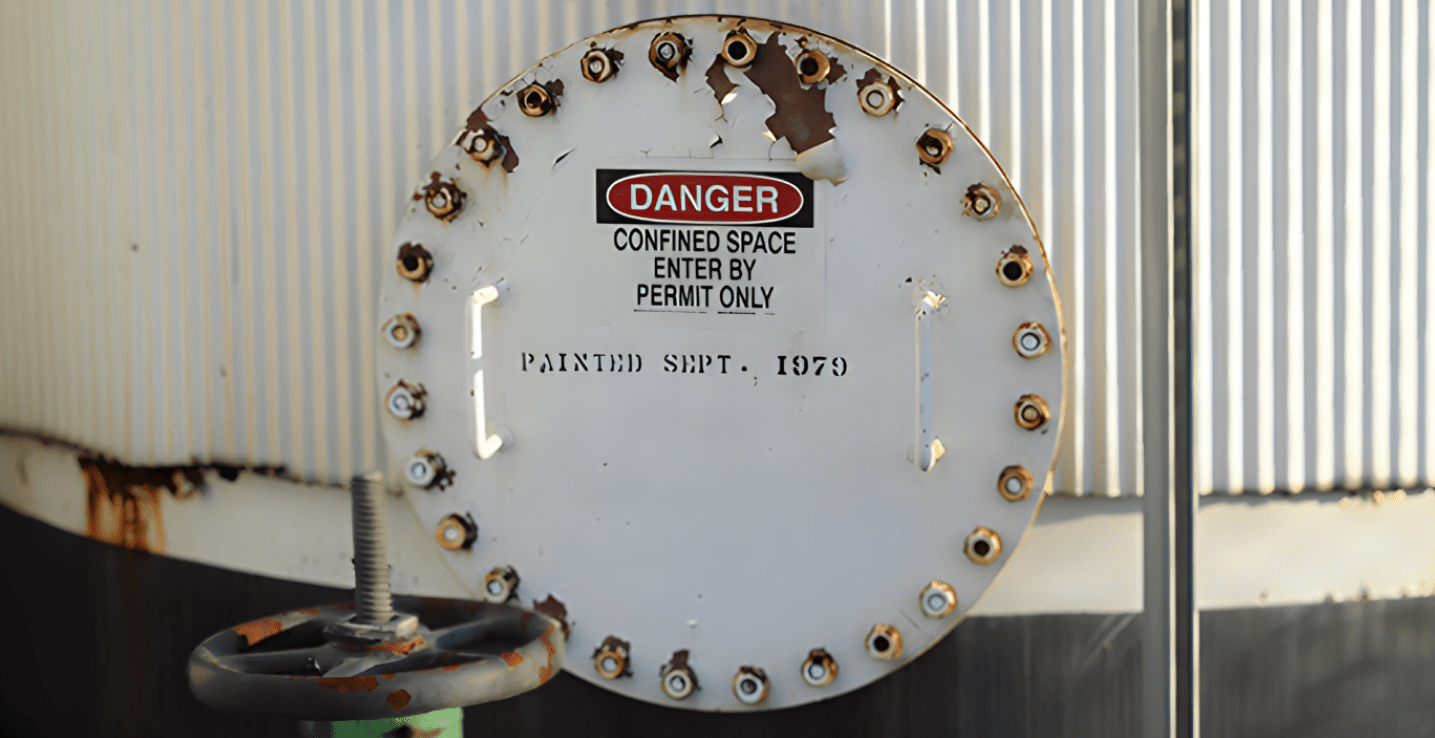

🔍 Click to Expand: Confined Space Entry & Attendant Training Overview

The **ACTI Confined Space Entry & Attendant Training Program** is designed to provide workers with the **knowledge and skills necessary to safely enter, monitor, and work in confined spaces**. This training aligns with ** OH&S regulations, CSA Z1006 standards, and industry best practices**, ensuring compliance and workplace safety.

Participants will learn how to **identify confined space hazards, implement control measures, follow safe entry procedures, and perform rescue operations**. The course covers **hazard assessment, atmospheric testing, isolation procedures, personal protective equipment (PPE), and emergency response**.

📌 Key Learning Modules:

- Legislation & Regulatory Requirements: Understanding OH&S, CSA Z1006, and employer/worker obligations.

- Hazard Identification & Control Measures: Recognizing common confined space hazards, including atmospheric, mechanical, and engulfment risks.

- Entry Procedures & Permits: Safe work permits, isolation, atmospheric monitoring, and attendant responsibilities.

- Personal Protective Equipment (PPE): Proper selection, use, and inspection of harnesses, respiratory protection, and gas detection equipment.

- Rescue Planning & Emergency Procedures: Understanding confined space rescue types, non-entry rescues, and emergency response planning.

✅ Upon Completion:

Upon successfully completing the **ACTI Confined Space Entry & Attendant Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA Z1006, and site-specific confined space entry requirements.

- ✅ **Conduct hazard assessments** and implement control measures to reduce risks.

- ✅ **Perform pre-entry atmospheric testing** and maintain safe conditions throughout the work process.

- ✅ **Properly use PPE and gas detection equipment** to ensure personal safety and compliance.

- ✅ **Carry out the duties of an attendant and entry supervisor** to oversee confined space operations.

- ✅ **Develop and execute emergency action plans** for confined space rescue situations.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI Confined Space Entry & Attendant Certification**, recognized across **Canada**, ensuring they are qualified to safely enter, monitor, and work in confined spaces within **industrial, construction, and maintenance environments**.

🔍 Click to Expand: Canadian DOT Cargo Securement Training Overview

The **ACTI Canadian DOT Cargo Securement Training Program** is designed to provide participants with the **knowledge and skills necessary to properly secure cargo in compliance with the North American Cargo Securement Standard**. This training aligns with **Canadian and U.S. federal regulations, Alberta OH&S standards, and industry best practices**, ensuring compliance and transportation safety.

Participants will learn how to **correctly restrain, immobilize, and inspect cargo to prevent load shifts, spills, and transportation hazards**. The course covers **securement system components, working load limits (WLL), tie-down methods, and commodity-specific requirements for various load types, including logs, metal coils, vehicles, and intermodal containers**.

📌 Key Learning Modules:

- Regulatory Standards & Compliance: Understanding North American Cargo Securement regulations, DOT guidelines, and employer/driver responsibilities.

- Securement System Components: Identifying vehicle structures, tie-downs, blocking, bracing, and friction-enhancing materials.

- Load Securement Techniques: Applying direct and indirect tiedowns, aggregate working load limit calculations, and best practices for various cargo types.

- Commodity-Specific Securement: Learning proper securement for logs, dressed lumber, metal coils, paper rolls, intermodal containers, vehicles, machinery, and roll-on/roll-off containers.

- Inspection & Compliance Checks: Conducting pre-trip, en-route, and post-trip inspections, identifying deficiencies, and ensuring regulatory compliance.

- Emergency Situations & Load Shifts: Responding to cargo securement failures, roadside inspections, and legal responsibilities for drivers and carriers.

✅ Upon Completion:

Upon successfully completing the **ACTI Canadian DOT Cargo Securement Training Program**, participants will be able to:

- ✅ **Understand and apply** North American Cargo Securement Standards and Canadian DOT requirements.

- ✅ **Identify appropriate securement systems** based on cargo type, weight, and vehicle configuration.

- ✅ **Correctly apply tie-downs, blocking, bracing, and securing devices** to prevent load movement.

- ✅ **Inspect and assess securement effectiveness** to ensure compliance with legal and safety requirements.

- ✅ **Respond to load shifts, securement failures, and emergency situations** to maintain roadway safety.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI Cargo Securement Certification**, recognized across **Canada**, ensuring they are qualified to secure loads safely and legally in **transportation, construction, and industrial environments**.

🔍 Click to Expand: Lift Truck Training Overview

The **ACTI Lift Truck Training Program** is designed to provide participants with the **knowledge and skills necessary to safely operate counterbalance and telescopic forklifts in various work environments**. This training aligns with **Alberta OH&S regulations, CSA B335 standards, and industry best practices**, ensuring compliance and workplace safety.

Participants will learn how to **conduct equipment inspections, operate lift trucks safely, handle loads correctly, and recognize hazards associated with lift truck operations**. The course covers **forklift classifications, stability principles, safe operating procedures, hazard awareness, and emergency response**.

📌 Key Learning Modules:

- Regulatory Standards & Compliance: Understanding OH&S requirements, CSA B335 standards, and employer/worker responsibilities.

- Lift Truck Anatomy & Components: Identifying key components, performing pre-use inspections, and understanding load capacity.

- Stability, Load Handling & Weight Estimation: Learning about center of gravity, balance principles, and proper load handling.

- Safe Operation & Driving Techniques: Maneuvering in various conditions, operating in high-traffic areas, and avoiding tip-overs.

- Common Hazards & Risk Prevention: Recognizing potential dangers such as pedestrian collisions, load instability, and power line contact.

- Emergency Preparedness & Incident Response: Implementing safe shutdown procedures, parking protocols, and emergency response planning.

✅ Upon Completion:

Upon successfully completing the **ACTI Lift Truck Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA B335 standards, and site-specific lift truck requirements.

- ✅ **Conduct pre-use inspections** and recognize defects that require maintenance or repair.

- ✅ **Safely operate counterbalance and telescopic forklifts** while maintaining stability and handling loads correctly.

- ✅ **Recognize common lift truck hazards** and implement best practices to prevent workplace incidents.

- ✅ **Develop and follow emergency response plans** for lift-related incidents and equipment failures.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI Lift Truck Operator Certification**, recognized across **Canada**, ensuring they are qualified to operate lift trucks safely in **construction, industrial, and warehouse environments**.

🔍 Click to Expand: Fall Protection Training Overview

The **ACTI Fall Protection Training Program** is designed to equip workers with the **knowledge and skills required to work safely at heights**, ensuring compliance with ** OH&S regulations, CSA Z259 standards, and industry best practices**.

Participants will learn how to **identify fall hazards, select appropriate fall protection systems, use equipment correctly, and develop rescue plans**. The course covers **regulatory requirements, fall arrest systems, anchor points, inspection procedures, and emergency response**.

📌 Key Learning Modules:

- Legislation & Worker Responsibilities: Understanding OH&S regulations, CSA Z259 standards, and employer/worker obligations.

- Hazard Recognition & Risk Assessment: Identifying common fall hazards and assessing worksite risks.

- Hierarchy of Controls: Exploring fall prevention, fall arrest, and fall restraint systems.

- Fall Protection Equipment: Proper selection, inspection, and use of harnesses, lanyards, anchor points, and self-retracting lifelines.

- Work Access & Platforms: Safe use of ladders, scaffolds, swing stages, and MEWPs.

- Emergency Response & Rescue Planning: Developing effective fall rescue plans and understanding suspension trauma risks.

✅ Upon Completion:

Upon successfully completing the **ACTI Fall Protection Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA Z259 standards, and worksite-specific fall protection requirements.

- ✅ **Recognize fall hazards** and implement control measures to reduce risks.

- ✅ **Properly inspect and use** fall protection equipment, including harnesses, lanyards, lifelines, and anchor points.

- ✅ **Safely work on elevated platforms, ladders, and scaffolds** while maintaining compliance with fall protection regulations.

- ✅ **Develop and execute emergency response plans** for fall-related incidents, including worker rescue.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI Fall Protection Certification**, recognized across **Canada**, ensuring they are qualified to work safely at heights in **construction, industrial, and maintenance environments**.

🔍 Click to Expand: MEWP Training Overview

The **ACTI Mobile Elevated Work Platform (MEWP) Training Program** is designed to provide participants with the **knowledge and skills required to safely operate MEWPs in various work environments**. This training aligns with ** OH&S regulations, CSA B354 standards, and industry best practices**, ensuring compliance and operational safety.

Participants will learn how to **identify hazards, conduct equipment inspections, operate MEWPs safely, and execute emergency procedures**. The course covers **MEWP classifications, stability principles, fall protection, safe work practices, and emergency response**.

📌 Key Learning Modules:

- Regulatory Standards & Compliance: Understanding OH&S requirements, CSA B354 standards, and employer/worker responsibilities.

- MEWP Types & Components: Identifying different types of MEWPs, their components, and required inspections.

- Pre-Use Inspections & Maintenance: Conducting daily inspections and understanding maintenance requirements.

- Safe Operation & Stability: Proper machine operation, load capacity, working on slopes, and avoiding tip-overs.

- Fall Protection & Worksite Safety: Implementing fall protection measures, hazard assessments, and exclusion zones.

- Emergency Preparedness & Rescue Plans: Understanding rescue procedures in case of machine failure or operator distress.

✅ Upon Completion:

Upon successfully completing the **ACTI MEWP Training Program**, participants will be able to:

- ✅ **Understand and apply** OH&S regulations, CSA B354 standards, and site-specific MEWP requirements.

- ✅ **Conduct pre-use inspections** and recognize defects that require maintenance or repair.

- ✅ **Safely operate MEWPs** while maintaining stability, avoiding hazards, and following proper work procedures.

- ✅ **Implement fall protection measures** and recognize the importance of safe work practices at height.

- ✅ **Develop and follow emergency action plans** for rescue operations and incident response.

- ✅ **Pass a written knowledge assessment** (minimum 80%) and successfully complete the practical evaluation.

Participants who meet all course requirements will receive an **ACTI MEWP Operator Certification**, recognized across **Canada**, ensuring they are qualified to operate MEWPs safely in **construction, industrial, and maintenance environments**.